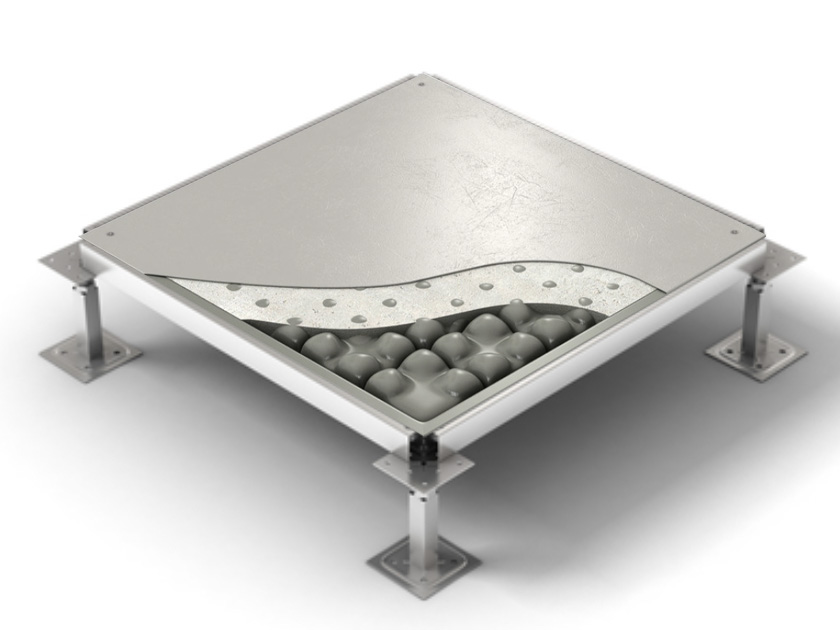

ConCore Panels

ConCore® Raised Access Floor panels are epoxy coated utilised shells consisting of a flat steel top sheet welded to a formed steel bottom sheet filled with a highly controlled mixture of lightweight cement infill. Manufactured to exacting tolerances, these non-combustible, rigid, panels deliver the ultimate in strength, durability, and acoustic performance.

Click

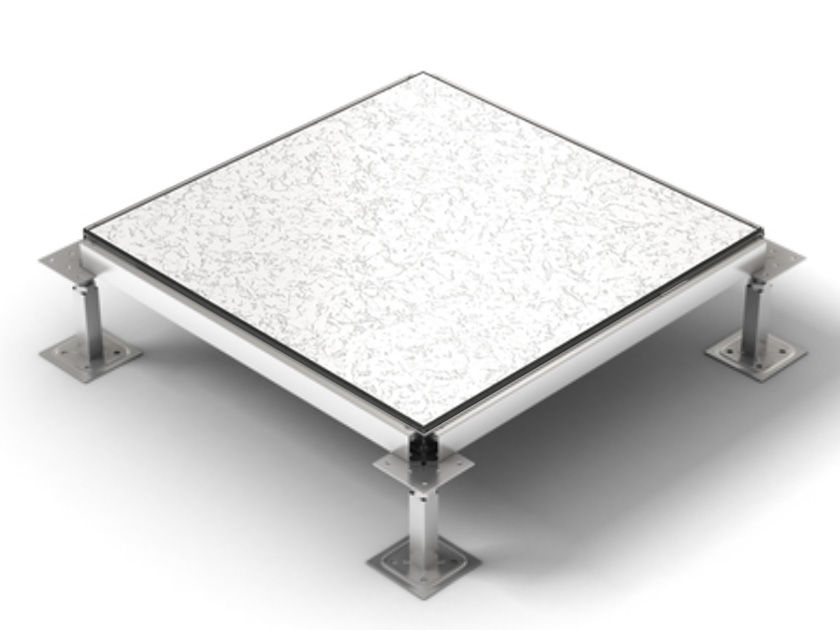

High Pressure Laminates

High Pressure Laminates (HPL) are most frequently used in data centres, service corridors, closets and other areas that require a durable finish or specific performance characteristics. Tate factory laminates the HPL to the access floor panel, reducing installation time and cost. HPL is the most common finish found in data centres, communciation closets and other back of house areas where there are requirements for low static generation, frequent access or ease of maintenance.

Click

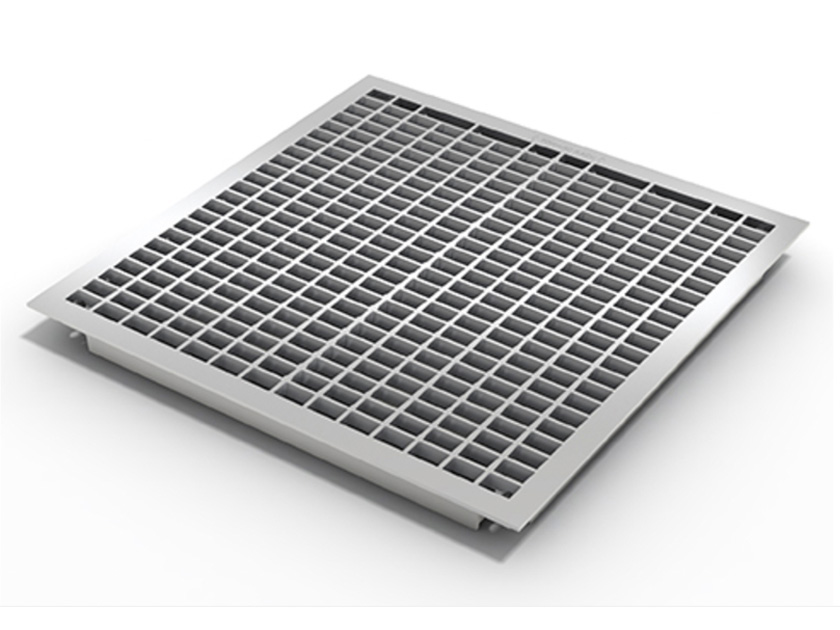

Airflow Panels

Tate Airflow has a full line of directional and vertical airflow panels to cater to all your data center cooling needs. Our range of cost-effective and energy-efficient airflow panels offer compelling returns on investment and lower operating costs in both new build and retrofit applications.

Click

Milliken Carpet

How well does Milliken cushion backing deal with moisture? Better than any product on the market. We say that confidently because we haven’t seen a moisture claim in more than 20 years.